Blog

China’s Most Trusted Industrial Valve Manufacturers

China’s Most Trusted Industrial Valve Manufacturers

China’s most trusted Industrial Valve Manufacturers include Chuanyi Automation, Neway Valve, XHVAL, SUFA Technology, Yuanda Valve Group, Plumberstar, Beijing Valve General Factory, China Valves Technology, Chaoda Valves Group, Oudian Valve, STV Valve, Topper Valve, PANS Valve, Formen Valve, Oilway, and AFC. These Industrial Valve Manufacturers are recognized for producing high-quality products such as Ball Valve, Globe Valve, Gate Valve, to Check. They hold key global certifications like API Q1 and ISO 9001, ensuring their products perform reliably in demanding environments. The market for these valves is valued at $78.2 billion and continues to expand. Choosing the right Industrial Valve Manufacturers for your Ball Valve, Globe Valve, Gate Valve, to Check is crucial for maintaining safety and efficiency in every project.

Key Takeaways

- People trust industrial valve makers when they give good quality, deliver on time, and help customers well. Top Chinese valve makers have important certificates like API Q1 and ISO 9001. These show their products are safe and high quality for the world. The best companies use new ideas and smart technology. This helps them make better valves that last longer for many jobs. Picking the right valve supplier means you must match your project needs with the right valve type, materials, and features. You also need to think about total cost and safety. Good after-sales service gives quick technical help and training. This helps things run smoothly and builds strong business friendships.

Trust in Industrial Valve Manufacturers

Quality Standards

Trust is very important when buying valves for important jobs. Many people who work in this field agree with this.

- A design engineer at Marubeni Citizen Cinco says it is important to trust that orders will arrive on time and be correct.

- A senior buyer at Moore Nano likes when suppliers give good engineering help, especially for special needs.

- A supply chain manager at MP Systems likes suppliers who answer fast and help fix problems.

These stories show that trust comes from always having good quality and being reliable. Industrial Valve Manufacturers need to follow strict rules to earn trust. The best companies use international rules that make sure products are safe, strong, and work well.

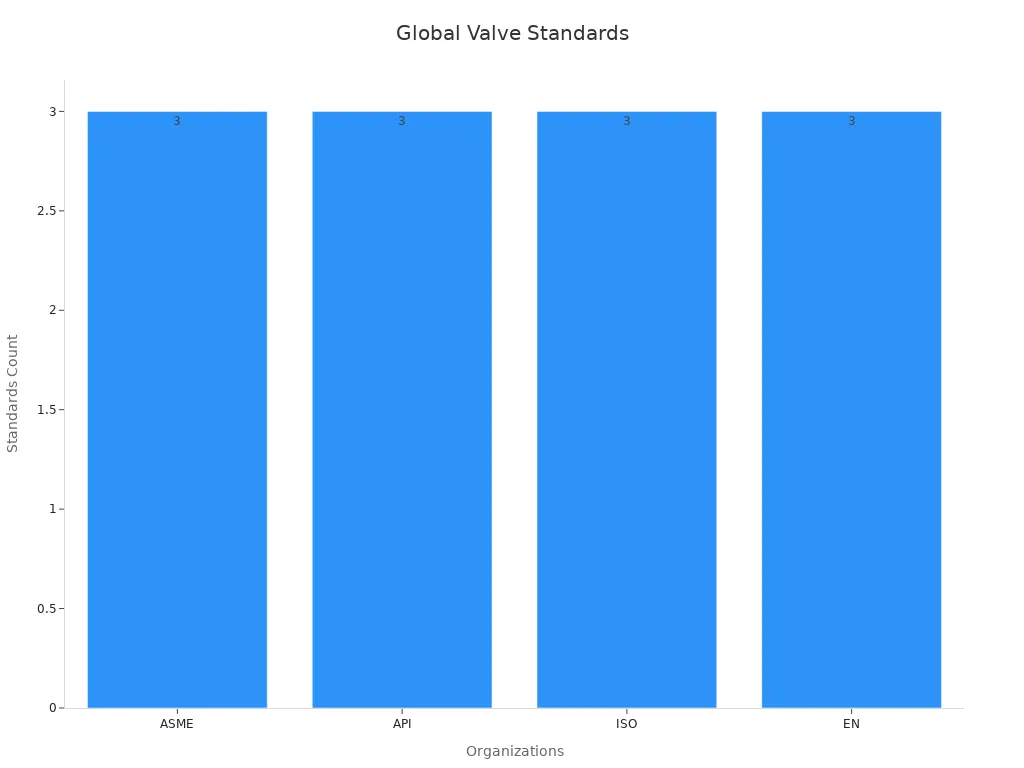

| Organization | Role/Scope | Examples of Relevant Valve Standards |

|---|---|---|

| ASME | Mechanical engineering codes and standards | ASME B16.34, ASME B16.10, ASME B16.24 |

| API | Oil and gas industry standards | API 6D, API 607, API 609 |

| ISO | International quality and safety standards | ISO 6002, ISO 1721, ISO 10631 |

| EN | European interoperability standards | EN 593, EN 1349, EN 1983 |

These rules help make sure valves work well in tough places.

Certifications

Certifications like API Q1 and ISO 9001 show a company meets world standards. These awards mean the company uses careful steps for design, making, and testing. Customers know certified products are safe and work well.

Innovation

Top companies spend money on research to make better products. For example, Emerson spent $280 million on research and made over 170 new valve models with digital features. Flowserve grew its size by 19% and made smart valve technology. These changes help valves last longer, work better, and help new fields like clean energy.

After-Sales Support

Good help after buying builds strong trust. Customers need help with putting in, fixing, and using valves. Fast answers and expert help stop problems and keep things working. Many buyers think this help is as important as the product.

Selection Criteria

Product Range

Having many types of products helps Industrial Valve Manufacturers meet more needs. Companies that sell ball, gate, globe, check, butterfly, and plug valves can help many industries. These include oil and gas, water treatment, and manufacturing. A big selection lets suppliers pick the best valve for each job. Some companies make valves for hydraulic, pneumatic, or fuel systems. Others work on smart features, better sealing, or making valves smaller. This makes it easier for companies to grow and stay ahead of others.

Tip: Having lots of products also helps with new projects and changing what customers want.

Compliance

Following industry rules keeps things safe and good quality. Manufacturers must obey rules from groups like ANSI, ASME, API, and ISO. These rules cover how valves are made, what they are made of, and how they are tested. Companies use strong safety plans, like checking equipment, teaching workers, and having plans for accidents. They also give test reports and material papers for each valve.

- Following rules stops leaks and problems.

- It keeps workers and the environment safe.

- It helps avoid big fines and legal trouble.

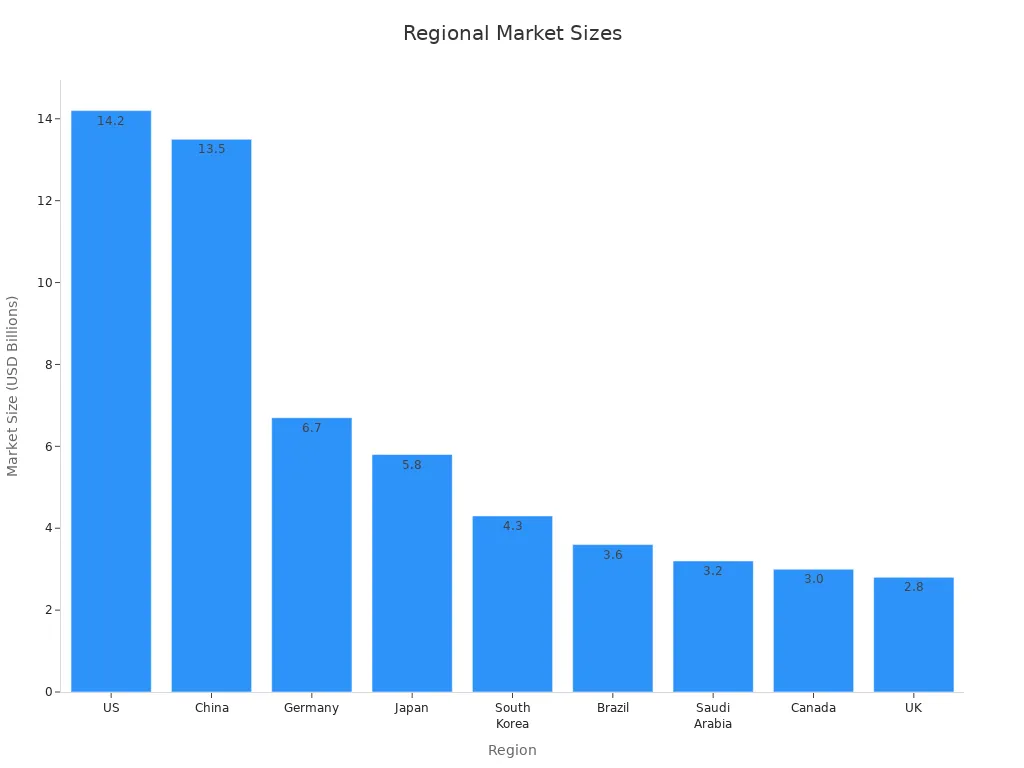

Global Reach

Top manufacturers work in many countries. They send valves to Europe, Asia-Pacific, the Middle East, and the Americas. The world market for industrial valves is now worth over $80 billion in 2024. Companies grow by building new factories and working with partners in other places. Being in many countries shows strong supply chains and meeting world rules.

Note: Working worldwide means faster shipping and better help for big projects.

Service

Good service makes people trust a company. The best manufacturers use sensors and AI to watch how valves work and find problems early. They give training, fix things, and answer questions fast. Customers can look at certificates, read reviews, and ask for samples before buying. Good service means less waiting, saving money, and keeping things working well.

- Warranties and promises help people feel safe.

- Customer reviews and online ratings help buyers pick good suppliers.

Top Industrial Valve Manufacturers

China makes more valves than any other country. Some companies are known for new ideas, good quality, and great service. Each company has something special to offer the world market.

The table below gives important facts about top companies. It shows their history, main products, and plans for the future.

| Manufacturer | Company Profile Summary | Revenue (2023) | Product Range & Innovation Highlights | Market Position & Industry Application | Future Outlook & Growth Areas |

|---|---|---|---|---|---|

| Chongqing Chuanyi | Founded 1965, largest automation instrument manufacturer in China, multiple top industry honors | N/A | Over a dozen product categories including automation control systems, 61 patents, predictive maintenance technologies | Strong in electricity, metallurgy, petrochemicals; recognized as high-tech enterprise | Focus on new-generation automation, intelligent instruments, expanding into nuclear power, urban rail, biomedical sectors |

| Neway Valve | Established 2009, global supplier with focus on high-end casting, fire safety, corrosion resistance | Approx. US$559M | Wide valve types (gate, globe, ball, butterfly, subsea, nuclear), 5000+ specs, breakthroughs in deep-sea and nuclear valves | Serves oil & gas, chemicals, polysilicon, power generation; strategic supplier to energy companies | Increasing market share in high-end products |

| Jiangsu Shentong | Specializes in special valves, 109 patents, 145 series, 2000+ products | N/A | Butterfly, ball, gate, globe, check, regulating, special valves; dominant market share in metallurgy and nuclear power valves | Core in metallurgy, nuclear power, energy chemical industries; expanding into hydrogen, aerospace, energy-saving services | Positioned for growth in new energy sectors like hydrogen, wind power, semiconductors |

| Zhonghe Sufa | Founded 1952, first publicly traded valve company in China’s nuclear sector | Approx. US$279M | Comprehensive valve solutions for nuclear, petrochemical, public utilities; strong certifications and brand recognition | Primary valve supplier for major nuclear groups and oil companies; strong domestic brand influence | Continues market-oriented, international strategies; expanding nuclear and petrochemical markets |

| YDF Valve | Advanced CNC machining, large valve processing capabilities | N/A | High precision manufacturing, extensive quality control, special performance test labs for ultra-low temp, high pressure tests | Significant domestic and international market presence; multiple certifications and awards | Focus on R&D, technological innovation, and market expansion |

| Harbin Power Station Valve | Founded 1954, part of Harbin Electric Group, mixed ownership reform completed 2020 | Approx. US$82M | 40+ valve series, 3000+ varieties; specializes in thermal, nuclear, solar thermal, petrochemical valves | Leading in high-temp, high-pressure thermal power valves; 70% market share in key applications | Strong R&D in supercritical power valves; recognized with national awards and patents |

Chuanyi Automation

Chuanyi Automation started in 1965. It is the biggest automation instrument maker in China. Chuanyi owns over 60 patents and has won many awards. The company makes ball, globe, and gate valves, plus smart control systems. Chuanyi works on smart valve technology and predictive maintenance. It helps electricity, metallurgy, and petrochemical companies. Chuanyi has strong certifications and invests in new automation. The company wants to grow in nuclear power, city trains, and medical fields.

Neway Valve

Neway Valve began in 2009. It sells valves all over the world. Neway is known for strong casting and fire safety. The company has over 5,000 valve types, like gate, globe, ball, butterfly, subsea, and nuclear valves. Neway has made new deep-sea and nuclear valve technology. It serves oil, gas, chemicals, polysilicon, and power companies. Neway has API and ISO certifications. The company is growing in high-end products.

XHVAL Group

XHVAL Group is known for good quality and trust. The company makes ball, gate, globe, check, and butterfly valves. XHVAL helps oil, gas, chemical, and water treatment companies. It uses advanced CNC machines and strict quality checks. XHVAL has ISO 9001 and API certifications. The company gives fast customer support and technical help.

SUFA Technology

SUFA Technology, or Zhonghe Sufa, started in 1952. It was the first valve company in China’s nuclear sector to go public. SUFA gives full valve solutions for nuclear, petrochemical, and public utilities. The company is well-known and has many certifications. SUFA is a main supplier for big nuclear and oil companies. It keeps growing in nuclear and petrochemical markets.

Yuanda Valve Group

Yuanda Valve Group, also called YDF Valve, uses advanced CNC machines and can make large valves. The company makes high-precision ball, gate, globe, and check valves. Yuanda sells in China and other countries. It has special labs for very cold and high-pressure tests. Yuanda focuses on research, new ideas, and growing its market.

Plumberstar

Plumberstar makes plumbing valves and fittings. The company sells ball valves, check valves, Y-strainers, and brass fittings. Plumberstar helps homes, businesses, and factories. It uses modern machines and strict quality checks. Plumberstar has ISO certifications and gives fast delivery and technical support.

Beijing Valve General Factory

Beijing Valve General Factory has made valves for a long time. The company makes gate, globe, check, and butterfly valves. Beijing Valve helps water, power, and chemical companies. It uses advanced production lines and strict testing. Beijing Valve has ISO and API certifications. The company is known for reliable products and good service.

China Valves Technology

China Valves Technology works on new ideas and exports. The company makes ball, gate, globe, check, and butterfly valves. China Valves helps oil, gas, water, and power companies. It invests in smart valve technology and automation. China Valves has API and ISO certifications. The company gives strong after-sales support and technical help.

Chaoda Valves Group

Chaoda Valves Group is known for stainless steel and special alloy valves. The company makes ball, gate, globe, check, and plug valves. Chaoda helps oil, gas, chemical, and marine companies. It uses advanced casting and machining. Chaoda has API, ISO, and CE certifications. The company focuses on exports and custom solutions.

Relia Valve

Relia Valve makes high-performance valves for tough jobs. The company sells ball, gate, globe, and check valves. Relia helps oil, gas, power, and chemical companies. It uses modern testing and quality checks. Relia has ISO and API certifications. The company gives technical support and quick answers.

Kosen Valve

Kosen Valve makes many kinds of industrial valves. The company sells ball, gate, globe, check, butterfly, and plug valves. Kosen helps oil, gas, water, and power companies. It uses advanced production and strict quality checks. Kosen has ISO and API certifications. The company is known for fast delivery and good service.

Topper Valve

Topper Valve works on automation and smart valve solutions. The company makes ball, gate, globe, check, and butterfly valves. Topper helps oil, gas, chemical, and water companies. It invests in research and digital valve technology. Topper has ISO and API certifications. The company gives technical support and training.

PANS Valve

PANS Valve is known for good quality and new ideas. The company makes ball, gate, globe, check, and butterfly valves. PANS helps oil, gas, water, and power companies. It uses advanced machines and strict testing. PANS has ISO and API certifications. The company gives fast delivery and customer support.

Formen Valve

Formen Valve makes custom valve solutions. The company sells ball, gate, globe, check, and plug valves. Formen helps oil, gas, chemical, and power companies. It uses modern production and quality checks. Formen has ISO and API certifications. The company focuses on exports and custom projects.

Oilway

Oilway makes valves for oil and gas jobs. The company sells ball, gate, globe, check, and butterfly valves. Oilway uses advanced machines and strict quality checks. The company has ISO and API certifications. Oilway gives technical support and fast delivery.

AFC (Advanced Flow Control)

AFC, or Advanced Flow Control, works on smart valve technology. The company makes ball, gate, globe, check, and butterfly valves. AFC helps water, power, and industrial companies. It invests in automation and digital valve solutions. AFC has ISO and API certifications. The company gives training and technical support.

The world market for industrial valves is growing quickly. China’s market may reach $13.5 billion in 2025. There is a big focus on advanced valve technology and making better products.

Industrial Valve Manufacturers in China keep leading in quality, new ideas, and service. Their products help many industries, like oil, gas, water treatment, and power.

Choosing the Right Manufacturer

Project Needs

Picking the right manufacturer starts with knowing what your project needs. Each job is different and has its own needs. The ‘Valve Trifecta’ helps teams look at quality, delivery, and price, in that order. Quality means using strong parts, good designs, and meeting rules like API or ISO. Reliable and on-time delivery stops costly delays. Safety is very important because a broken valve can cause big problems. Teams should think about the total cost, not just the price to buy.

- Think about what kind of valve you need for flow control.

- Make sure the valve material fits the fluid, like if it is corrosive or rough.

- Check if the pressure and temperature ratings fit your project.

- Look at valve features, like tight shut-off or if it can be automated.

| Selection Criteria | Description |

|---|---|

| Valve Type | Pick based on how you want to control flow and how the valve works (like ball, butterfly, check valves) |

| Media Characteristics | Choose materials for fluids that are corrosive, rough, or need to stay clean |

| Pressure/Temperature | Match ratings to what your project needs |

| Sizing (Cv) | Make sure the size is right for how much flow you need |

| Valve Features | Check for things like tight shut-off, control, and automation |

| Materials of Construction | Make sure the valve material works with the fluid and the place it will be used |

Credentials

A good manufacturer has strong credentials. Certifications like API, ISO, and CE show the company meets world standards. Many Industrial Valve Manufacturers also have welding and inspection certificates, like Certified Welder or ANST NDT Level II. These show the company follows strict safety and quality rules. Companies often give papers, like test certificates and inspection reports, to prove they follow the rules. Training and learning new skills help teams keep up with changes in the industry.

Support

Customer support is very important for long-term happiness. Top manufacturers give fast technical help, warranty, and help with repairs. They offer spare parts and training for putting in and fixing valves. Good support means less downtime and keeps things working well. Many companies use customer service goals to check and improve their help. Certifications like ISO and API also show they care about good support.

Tip: Good support helps build strong business ties and makes projects work better.

Samples

Asking for samples lets teams test how valves work before buying a lot. Manufacturers often give sample valves for flow and pressure tests. These tests use special tools to check flow, pressure, and how the valve works. Automated systems give quick and correct results. Some companies use smart quality control with real-time data to watch performance. Testing samples helps make sure the valves fit the project and meet world standards.

Reliable Chinese valve suppliers are known for good product quality, important certifications, and helpful customer support. These things help buyers avoid problems and get better project results.

- Companies with a good history give steady performance.

- Certifications prove they care about safety and follow rules.

Buyers should always check if the supplier’s strengths fit their project needs. For more information or to get a price, contact the companies listed.

FAQ

What certifications do top Chinese valve manufacturers hold?

Most top manufacturers have API and ISO certifications. These show the company follows world safety and quality rules. Buyers can ask for copies of these certificates to check.

How can buyers verify product quality before placing large orders?

Buyers can ask for product samples to test them. Many companies give test reports and inspection papers.

Tip: Always look at third-party inspection results for extra safety.

Do Chinese valve manufacturers offer custom solutions?

Yes, many companies make custom valve designs. They work with customers to fit special project needs.

- Custom options can include different materials, sizes, or automation.

What is the typical lead time for industrial valve orders?

Lead times change by order size and product type. Most standard products ship in 2–6 weeks. Custom orders can take more time.

Note: Talking early with the company helps stop delays.

What after-sales support do these manufacturers provide?

Manufacturers give technical help, spare parts, and training. Many offer warranties and answer service requests fast.

Customers can call support teams for help with setup or fixing problems.

1 comment on “China’s Most Trusted Industrial Valve Manufacturers”

Oudianvale

300LB Cast Steel Gate Valve,6 Inch Cast Steel Gate Valve,RF End Cast Steel Gate Valve