Blog

Ball Valve vs Butterfly Valve Key Differences and Best Uses

Comparing Ball and Butterfly Valves for Industrial Use

Explore key differences and best uses of ball and butterfly valves.

| Features | Butterfly Valve vs Ball Valve | Butterfly Valve vs Ball Valve |

|---|---|---|

| Operation Mechanism | Rotating ball with hole aligns flow. | |

| Sealing Capability | Excellent seal; zero leakage when closed. | |

| Suitable Pipe Size | Best for small to medium pipes up to DN 100. | |

| Weight and Space | Heavier; requires more installation space. | |

| Pressure and Temperature | Handles high pressure and temperature robustly. | |

| Flow Control | Quick ON/OFF; limited fine flow control. | |

| Cost | Higher initial cost and maintenance. | |

| Maintenance Needs | More complex; seals wear with use. | |

| Suitability for Pigging | Suitable for piggable systems. | |

| Best Use Cases | High pressure, tight shut-off, fast cycling. |

Choosing a ball valve or a butterfly valve changes how a system works and costs money. The valve you pick controls flow, pressure, and temperature. New data shows the control valve market is growing fast. Many industries need the right valve for good results and trust. There are big differences in weight, sealing, and space needed. Butterfly valves are about 75% lighter and use 84% less space than ball valves of the same size. But ball valves usually seal better when pressure is high.

Key Takeaways

- Ball valves close very tightly and are good for high-pressure jobs that need fast ON/OFF control. Butterfly valves are lighter, use less space, and work well in big pipes with smooth flow control. Use ball valves for small pipes, tight closing, and systems that turn on and off a lot. Choose butterfly valves to save money, use in big pipes, and make putting in and fixing easier. Think about pressure, pipe size, fluid type, and cost when picking the best valve for your system.

Key Differences

Operation

Ball valves and butterfly valves both turn a quarter to open or close. But they work in different ways. A ball valve has a round ball with a hole in it. When you turn the handle, the hole lines up with the pipe. This lets fluid move through. If you turn the handle again, the hole turns away and blocks the flow. This makes it easy to see if the valve is ON or OFF. A butterfly valve has a flat disc on a shaft. Turning the handle spins the disc inside the pipe. If the disc is flat with the flow, fluid moves through. If the disc stands up, it blocks the flow. The disc always stays in the way, even when open.

Note:

A 2025 study used computer models to look at flow in ball valves. It found that the flow coefficient (Cv) changes in a non-linear way with speed and valve position. At low speeds, turbulence can make the flow unstable, especially if one side is closed. The study also showed that pressure drop gets bigger as speed goes up, especially when the flow path is tight. This means both the valve type and how much it is open change how well the valve works.

Design

Each valve’s design changes how it works best. Ball valves have a round body with a ball inside. The ball has a hole in the middle. The handle turns the ball to control flow. This makes ball valves heavier and bigger, especially in large sizes. Butterfly valves have a thin, disc-shaped part that closes the pipe. The disc is on a shaft in the center. The body is lighter and fits in less space between pipes. This makes butterfly valves easier to put in small spaces and better for big pipes. A recent study compared valve designs and found that the shape and type of valve matter a lot for how well it works. The study looked at things like flow area and pressure drop. It found that some design features, like the type of closure and how it moves, can help flow and lower resistance. Picking the right design can make a system work better and last longer.

Sealing

| Valve Type | Sealing Capability Description |

|---|---|

| Ball Valve | Provides zero leakage when fully closed due to fluid pressure pushing the ball against the seal, ensuring a positive shutoff. Reliable sealing even at high pressure differences. |

| Butterfly Valve | Provides an excellent seal at low pressure but is less reliable than ball valves at high pressure. Leakage rates can be influenced by operating conditions such as temperature, pressure, and humidity. |

Ball valves shut tightly and do not leak when closed. The ball presses hard against the seat to make a strong seal. This is good for jobs where leaks are not allowed. Butterfly valves also seal well, mostly at low pressures. But their seal can change with pressure, temperature, and humidity. At high pressures, butterfly valves might let some fluid leak.

Flow Control

Ball valves and butterfly valves control flow in different ways. Ball valves are quick for ON or OFF use. They are best for jobs that need full open or full closed. Some ball valves, like V-port types, can control flow better, but most are not made for fine control. Butterfly valves can adjust flow more smoothly. The disc can turn to different angles to change the flow. This makes butterfly valves good for systems that need both shut-off and flow control. But the disc always stays in the flow, so there is a small pressure drop even when open.

- Ball valves are best for tight shut-off and high-pressure jobs.

- Butterfly valves are lighter, easier to put in big pipes, and better for flow control in low to medium pressure jobs.

Ball Valve Overview

How It Works

A ball valve has a round ball with a hole in it. When you turn the handle, the ball spins inside the valve. If the hole matches the pipe, fluid can move through. Turning the handle all the way blocks the flow. The main parts are the body, ball, seats, stem, and lever. Diagrams show how these parts fit together. The seat is soft and helps the ball seal tightly. Animated guides show the ball moving inside, which makes it easy to see how it works. Ball valves come in many types like floating, fixed, V-type, and three-way. Each type is good for different jobs.

Advantages

Ball valves have many good points over butterfly valves. They shut off tightly, so there are no leaks when closed. You can open or close them fast with a quarter-turn. Ball valves let fluid move easily when open. They are easy to fix because the parts are simple to reach. Industry data says automated ball valves help save money and energy. The market for these valves is getting bigger and will reach $4.8 billion by 2033. These valves also work with smart tech for remote checks and repairs. Ball valves are strong in high-pressure and high-temperature systems. This makes them good for tough jobs.

Tip:

Ball valves are great for systems that need a strong seal and quick shut-off, especially in small pipes.

Disadvantages

Ball valves do have some problems, mostly in high-pressure places. Studies show leaks can happen if the sealing rings wear out or get scratched. These leaks are hard to find but can be unsafe in pipelines. High pressure can hurt the seats or make them change shape. Problems with metal, like bad heat treatment, can cause failure even at low pressure. Ball valves can also wear out if used a lot, which hurts their seal over time. These issues mean ball valves are not always best for high-pressure or very important jobs.

Butterfly Valve Overview

How It Works

A butterfly valve has a flat, round disc on a shaft in the pipe. When you turn the handle, the disc spins a quarter turn. If the disc matches the flow, fluid moves through easily. If the disc stands up, it blocks the flow. The disc always stays in the flow, even when open. This design lets you open or close the valve quickly. It is easy to tell if the valve is open or closed. Many industries use butterfly valves to stop or control flow.

Advantages

Butterfly valves have many good points compared to ball valves:

- The body is light, so it is easy to put in big pipes.

- The small shape fits well in tight places.

- You can open or close it fast with a quarter turn.

- Big sizes cost less, which helps save money.

- Good for systems that need to open and close often.

- Works well with water, air, and many chemicals.

- Comes in many sizes, even very large ones.

Tip:

Butterfly valves are best when space, weight, and cost are important.

Disadvantages

Butterfly valves also have some problems when compared to ball valves. In oil and gas, valve problems can cause big trouble. These problems can stop work, hurt the environment, or put workers at risk. Some common issues with butterfly valves are:

- Seals can wear out and cause leaks.

- High or low temperatures or pressure can damage the valve.

- Dirt or rough bits in the pipe can cause problems.

- Some fluids do not work well with the valve’s material.

- Bad assembly or installation can cause trouble.

These problems can make the valve less reliable and need more repairs. Butterfly valves are good for many jobs, but they may not seal as tightly or last as long as ball valves in high-pressure or important systems.

Comparison Table

Picking the right valve is important for many reasons. Engineers look at ball valves and butterfly valves to see which works best. The table below shows the main ways these valves are different. Each row tells how the valves work in real life.

| Feature | Butterfly Valve | Ball Valve |

|---|---|---|

| Sealing | Good at low pressure; may leak at high pressure | Excellent; provides zero leakage when closed |

| Flow Control | Allows near-linear flow adjustment; disc always in flow | Quick ON/OFF; full bore for minimal pressure drop |

| Size Range | Suitable for large pipes (up to DN 700); compact body | Best for small to medium pipes (up to DN 100); bulkier design |

| Weight | Lightweight; easy to handle and install | Heavier; requires more support |

| Pressure/Temperature | Handles low to medium pressure; moderate temperature range | Handles high pressure and temperature; robust construction |

| Cost | Lower purchase and installation cost; less material used | Higher initial cost; more material and shipping cost |

| Maintenance | Less frequent; simple design; easy to service | More frequent for seals; parts may wear with heavy use |

Note:

Butterfly valves need less force to turn, even when big. They open and close faster, so they are good for quick jobs. Ball valves seal better and can take more pressure, but they need more force to use and cost more to automate.

Tests show a 2-inch butterfly valve needs about 15–25 Nm of force. A 2-inch ball valve needs 25–40 Nm. Butterfly valves open and close faster, which helps in fast systems. Ball valves are more exact and repeat the same shut-off, so they are best when no leaks are allowed.

Butterfly valves cost less to buy and put in. They are light, so shipping is cheaper too. They do not need much care or fixing. Ball valves may need more checks, especially if used a lot or in tough places.

This table helps people see what each valve does well and where it is weak. It helps them pick the best valve for their job.

Choosing a Valve

Picking the right valve depends on many things. Every system is different, so engineers must check pressure, pipe size, space, cost, and fluid type. The table below shows how ball valves and butterfly valves compare:

| Feature/Criteria | Ball Valves | Butterfly Valves |

|---|---|---|

| Pressure Handling | Best for high pressure; excellent sealing | Good for low to medium pressure |

| Pipe Diameter | Suited for small pipes (less than 6 inches) | Ideal for large pipes (over 2 inches) |

| Media Type | Works with liquids and gases | Best for water and non-corrosive fluids |

| Pigging Requirement | Suitable for piggable systems | Not suitable for pigging |

| Cycle Times | Handles fast cycling | Less suitable for frequent cycling |

| Leakage and Sealing | Tight shut-off, minimal leakage | May leak at high pressure |

| Installation Space | Needs more space, heavier at large sizes | Compact, lighter even in big sizes |

| Maintenance | More complex, higher cost | Simple, easy, and less expensive |

| Cost | Higher initial cost | Lower setup cost |

Tip:

If your pipe is bigger than 2 inches, butterfly valves usually cost less and are easier to automate. Ball valves are better for high-pressure or high-temperature jobs.

Performance Metrics Matter

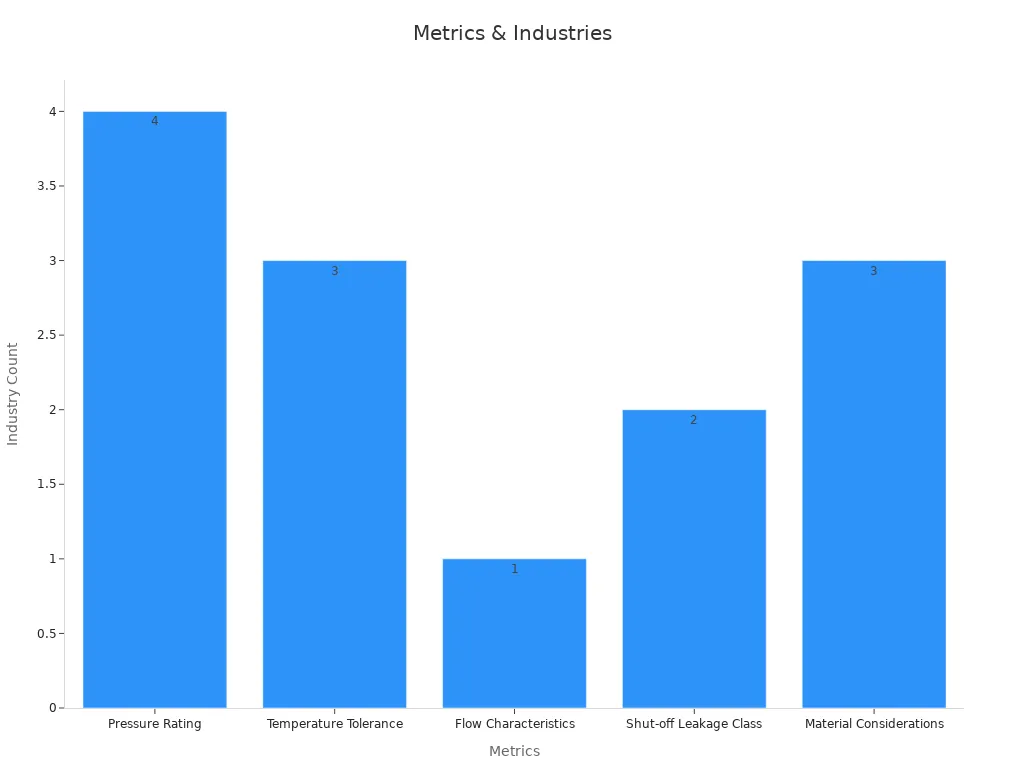

Engineers use special numbers to match valves to each job. Pressure rating, temperature tolerance, flow, and shut-off class all matter. The chart below shows how different industries use these numbers to pick valves:

- Pressure rating means how much force a valve can take. Oil, gas, chemical, and power plants need valves that meet tough rules.

- Temperature tolerance tells which materials to use. Food, drink, and chemical plants often need valves that can handle heat.

- Flow features, like the valve coefficient (Cv), help engineers choose the right size and type.

- Shut-off leakage class shows how well a valve stops leaks. Food and process plants often need the tightest shut-off.

Real-World Scenarios

Some real-life stories show how picking the right valve helps:

- In oil and gas, a company changed from ball valves to triple offset butterfly valves to stop leaks. The new valves gave zero leaks and worked better.

- Water treatment plants use resilient seated butterfly valves because they seal tight and resist rust.

- A power plant made cooling better by using high-performance butterfly valves that can take more heat and pressure.

Selection Tips

When you pick between ball valves and butterfly valves, think about these things:

- Use a ball valve for high pressure, tight shut-off, piggable systems, small pipes, and fast cycling.

- Pick a butterfly valve for big pipes, lower pressure, water, projects that need to save money, and small spaces.

- For sanitary jobs, both valves work if made from stainless steel and easy to clean.

- Maintenance and long-term costs are important. Butterfly valves usually cost less to keep working because they are simple.

- New tissue valves in hospitals show that strong valves and less fixing can save money over time. Systems that need fewer repairs and less checking often cost less in the end.

Note:

Some jobs can use either valve type. In these cases, engineers should look at what the system needs, like pressure, temperature, and how often the valve will open and close.

Quick Reference List

- High pressure or gas: Ball valve

- Large diameter or water: Butterfly valve

- Tight shut-off needed: Ball valve

- Cost-sensitive or space-limited: Butterfly valve

- Frequent cycling: Ball valve

- Simple maintenance: Butterfly valve

Picking the right valve keeps systems safe, saves money, and stops delays. Each job has a best choice, so comparing options helps get the best results.

The table below shows the main differences and best uses for each valve type:

| Valve Type | Best Use Case | Flow Control Level |

|---|---|---|

| Ball Valve | Quick shutoff | Low |

| Butterfly Valve | Large pipelines | Medium |

When picking a valve, think about these things:

- What kind of fluid or gas will go through it

- The temperature and pressure the valve will handle

- How much flow you need

- How easy it is to put in and take care of

Picking the right valve helps your system work well and saves money. Every system is different, so you need to look at what it needs to get the best results.

FAQ

What is the main difference between a ball valve and a butterfly valve?

A ball valve has a round ball inside to stop or let flow. A butterfly valve uses a flat disc to do the same job. Ball valves seal tightly and work well when pressure is high. Butterfly valves are lighter and fit better in big pipes.

Which valve is easier to install in tight spaces?

Butterfly valves are small and light. They fit well in tight spots and big pipes. Ball valves are heavier and need more space, especially if they are large.

Which valve type is better for precise flow control?

Butterfly valves can change flow smoothly because the disc turns to many angles. Ball valves are best for quick ON or OFF, not for small flow changes.

Are both valves suitable for high-pressure applications?

Ball valves work well with high pressure and shut off tightly. Butterfly valves are best for low or medium pressure. High pressure can make butterfly valves leak.

Which valve costs less for large diameter pipes?

Butterfly valves are cheaper for big pipes. Their simple shape uses less material and weighs less. Ball valves get heavy and cost more as pipe size gets bigger.